MINIMIZE COMPRESSED AIR LEAKS | Leaks Repair | Compressed Air Audit Services

|

| MINIMIZE COMPRESSED AIR LEAKS | Leaks Repair |

Leaks are a significant source of wasted energy in a compressed air system, often wasting as much as 20-30% of the compressor’s output. Compressed air leaks can also contribute to problems with system operations, including:

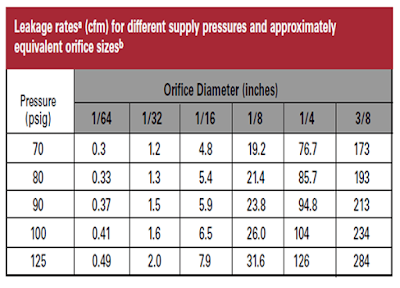

Although leaks can occur in any part of the system, the most common problem areas are: couplings, hoses, tubes, fittings, pipe joints, quick disconnects, FRLs (filter, regulator, and lubricator), condensate traps, valves, flanges, packings, thread sealants, and point of use devices. Leakage rates are a function of the supply pressure in an uncontrolled system and increase with higher system pressures. Leakage rates are also proportional to the square of the orifice diameter. (See table below.

|

| Leaks Repair | Logo |

Leaks Repair offers a wide range of Compressed Air Energy Management Solutions & Industrial Energy Saving & Energy Saving Equipment Singapore,Indonesia & UAE.

We have able service teams located at our offices with experience to carry out leakage management programs and document the same in an easy to read format so that the user has a good idea about the present status of their compressed air or gas piping system including the equipments and accessories involved.

The entire Leakage Management Program being online, records can easily be accessed at anytime from anywhere and a reference can be made so that the overall improvement or degradation of the plant can be assessed and rectified. We strive to ensure to save energy and improve efficiencies of systems involving gases. We partner with premier engineering companies to provide good quality spares and replacements. The effect of our endeavours is felt gradually over a period of time based on completion of the modules presented in the program.

The entire Leakage Management Program being online, records can easily be accessed at anytime from anywhere and a reference can be made so that the overall improvement or degradation of the plant can be assessed and rectified. We strive to ensure to save energy and improve efficiencies of systems involving gases. We partner with premier engineering companies to provide good quality spares and replacements. The effect of our endeavours is felt gradually over a period of time based on completion of the modules presented in the program.

Comments

Post a Comment